THE GCAL ADVANTAGE

WHY GCAL? Glad you asked. Here are some of our Exclusives and Testimonials.

SARINE DIAMOND JOURNEY™

FROM ROUGH TO POLISHED-

NEW LEVEL OF CONSUMER CONFIDENCE

Sarine offers the highest level of assurance and security with verifiable traceability data from an independent third party.

-

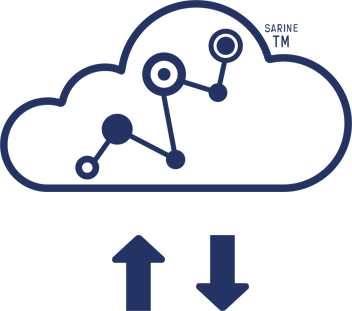

SCALABLE SOLUTION YOU CAN RELY ON

Diamond Journey™ report platform leverages deployed infrastructure and integrates seamlessly into existing manufacturing processes.

-

VERIFIABLE DIAMOND DATA

The diamond’s identity is validated by data throughout every step of its journey, giving buyers complete confidence in their purchase.

-

SUSTAINABILITY WITH TRUE TRACEABILITY

Satisfy socially conscious consumers’ need for verifiable proof of their diamond’s provenance and journey.

-

ENHANCE BRAND DIFFERENTIATION

Available as a customizable 'white label' solution for your brand.

THE ONLY VERIFIABLE TRACEABILITY FROM ROUGH TO POLISHED

STAGES

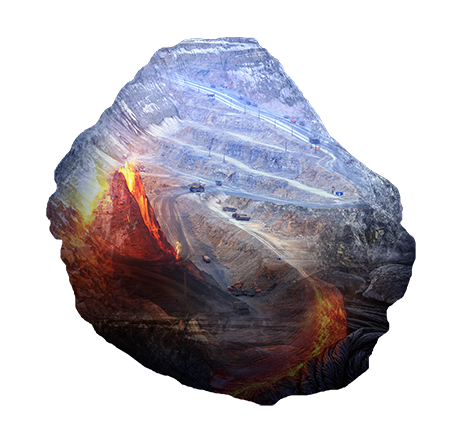

LET'S SEE ALL THE STAGES DIAMONDS ARE PASSINGMINING - THE BEGINNING OF THE DIAMOND JOURNEY - THE TRUE PROVENANCE OF A DIAMOND

SURFACING THE ROUGH DIAMOND

Why do humans prize diamonds above all other stones? Perhaps it’s the incredible geological story of their origin, their provenance, some 3 billion years ago, deep beneath the Earth’s surface, as intense pressure and temperature compressed ordinary carbon into the hardest crystals in nature. then these stones were brought to the surface by cataclysmic volcanic activity. This explains why no two natural diamonds are alike. And why, it takes highly sophisticated mining methods and much time to extract rough diamonds.

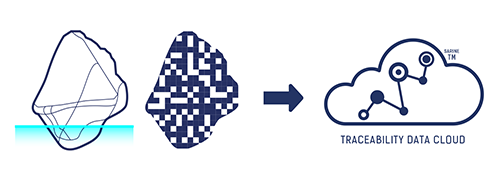

SCANNING - TRACEABILITY STARTS

Sarine Diamond Journey™ Traceability begins with a 3D scanning procedure, done by the miner, to create a verifiable image of the physical diamond and a definitive link to its digital report. This enables the creation of an unbroken chain of authentication at every stage of the diamond’s journey – from rough to rough, rough to polished, polished to report. Securely stored in the cloud, this data provides the foundation of true end-to-end Traceability.

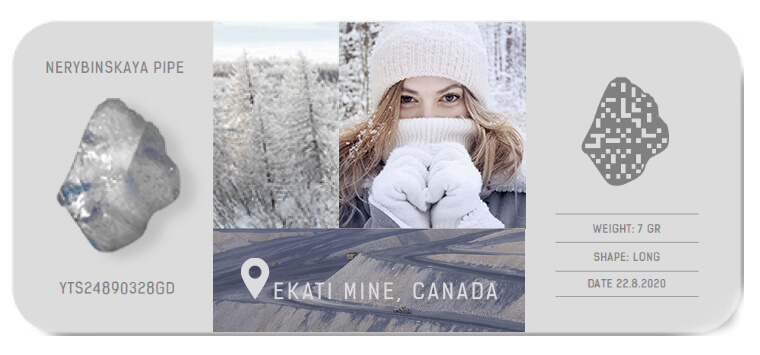

BIRTH REGISTRATION ID

Just like a newborn, we give every rough diamond emerging from the mine its own Birth Registration ID. At the mine each rough stone is digitally scanned, creating a unique 3D model. Other important identifying data, such as country of origin, is registered and the data is uploaded to Sarine’s secure cloud based system.

MANUFACTURE

ROUGH VERIFICATION

Sarine Diamond Journey™ Traceability continues at the manufacturer with Rough Verification. After being traded across countries and continents, upon arrival at the polisher’s facilities each rough stone is scanned again. Sarine’s unique verification algorithm matches the rough stone to what was initially registered by the producer. Once the match is ascertained, the stone is registered with its new owner. In the case of a negative match, the manufacturer is alerted instantly.

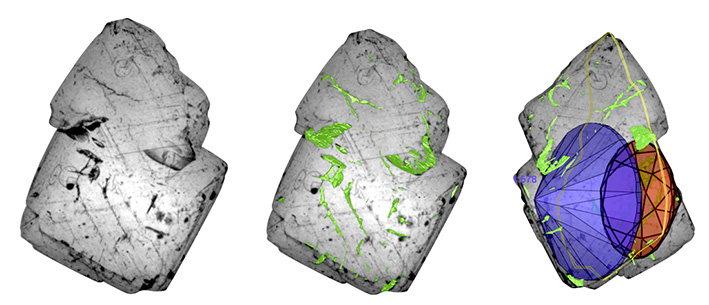

MAPPING – UNDERSTANDING THE DIAMOND’S TRUE VALUE

Just like a human fingerprint, every rough diamond has unique characteristics that can be determined using Sarine’s advanced diamond mapping technology. For instance, Sarine Galaxy® imaging scans the rough diamond to reveal its internal birthmarks, DiaExpert® maps the diamond’s external surface, and Sarine Advisor® software analyzes the rough diamond to explore the polished diamond’s aesthetic and financial value potential.

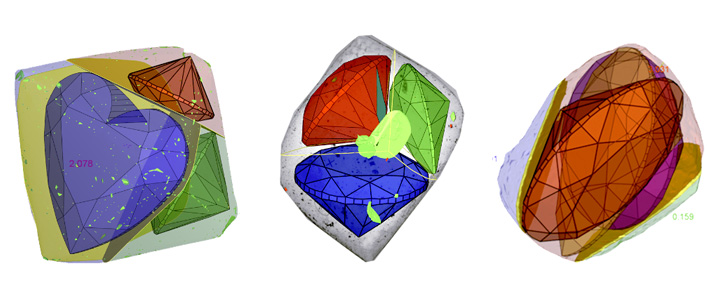

PLANNING THE PERFECT CUT

There are infinite ways to cut and polish a rough diamond. Depending on its origin, size, birthmarks, and features, the expert must decide upon the best cutting plan for the rough diamond to bring out its latent beauty, and value. Using Sarine's planning technology, the optimal cutting plan is determined to achieve the perfect cut.

When the polished plan is finalized, Sarine Diamond Journey™ Traceability captures multiple images and documentary information pertaining to the expected transition process from rough to planned polished.

SAWING - A DELICATE PROCESS OF SKILL AND PRECISION

Creating the finished diamond from the hardest material on earth requires painstaking care and craftsmanship. Sarine’s Quazer® is a leading choice for high quality laser sawing. This delicate procedure requires skill, patience and the most advanced technology to ensure the natural diamond is sawn to the most exacting standards of precision.

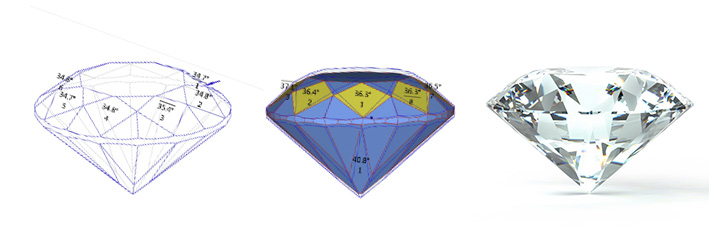

POLISHING REVEALS THE DIAMOND’S ULTIMATE BEAUTY

Polishing represents the final stage in the naturally-sourced diamond’s journey in becoming an exquisite finished gem. The diamond is periodically scanned with the DiaMension® HD technology, to ensure that the diamond cutter is adhering to the cutting plan.

Once polishing is complete, the polished stone is matched against previously documented actual and expected features for validation. The ID is once again registered by the manufacturer.